With the current COP26 conference happening in Glasgow on 31st October – 12th November 2021 this is our second blog post in relation to pathways for a low carbon future. Today we discuss electrification of industry processes, this including sectors that produce goods and raw materials we use every day. Electrification refers to replacing conventional processes that use fossil fuels with technologies that use electricity.

Accelerating the phase-out of coal has been a huge discussion point so far in COP26, with the UK being in the top 20 countries that emit the most carbon dioxide. Emissions from the industry sector are a contributor to this and globally are an even greater contributor from countries with large manufacturing outputs and industrial economies like China, USA and Japan. Substituting fossil fuels for alternative energy sources can significantly reduce CO₂ emissions across several industries which is the main greenhouse gas emitted from industrial processes.

Rising CO2 concentration in the atmosphere and its effect on the global climate has led governments setting binding targets for reduced emissions and plans for a net zero economy. To achieve net zero industry and energy use will have to shift significantly in utilising electricity and hydrogen far more widely than in the current energy mix.

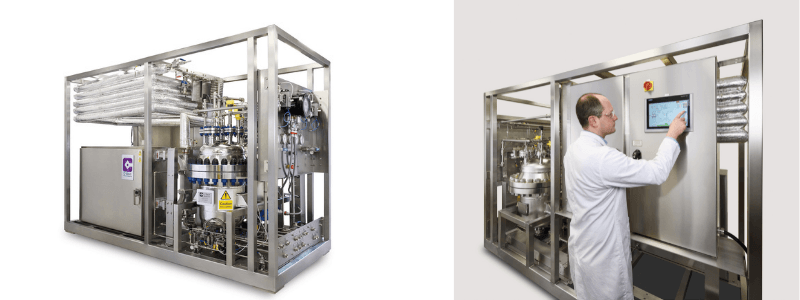

One pathway to electrification is switching from batch heating processes to continuous flow, this technology saves on cost, energy and time. Continuous flow heating technologies offer significant advantages compared to traditional batch manufacturing methods and transforms efficiency and costs for the fine chemical, specialty chemical and pharma related sectors.

As well as these advantages, electrifying production brings benefits to the environment, such as reduced CO₂ emissions through more efficient use of heat, the option to use energy from a renewable source and long-term production sustainability. Continuous flow heating technology is more environmentally friendly with much lower energy consumption than batch methods. However still meets critical temperature requirements for many production industries (such as pharmaceutical and chemical), whilst reducing overall footprint. This technology helps to make processes more efficient and precise by having a more uniformed heat delivery and precise temperature control.

The electrification of thermal processes will have a key role in the decarbonisation of industry sectors, in light of the goals set from COP26, companies in this sector need to be willing to adapt and must make significant changes in their current processes to reduce their overall carbon footprint. Adopting continuous manufacturing methods by integrating more modern and sustainable electrical heating technologies is key to achieving low carbon goals.

With 20 + years of experience, delivering novel continuous process technology is one of our core capabilities. With multiple global projects involving a variety of industries our technology is leading the way in process electrification.

Read more about process electrification here:

Learn More