The lifecycle of a nuclear power plant is typically about 30-40 years, it is expected that by 2040, 411 nuclear facilities are to be decommissioned [1], with this comes a wide range of nuclear waste needing to be stored, treated, and disposed of, if nuclear power is going to remain a viable low carbon energy source for the future, then this accumulating waste needs to be reduced.

The decommissioning of nuclear plants means the clean-up of radioactive plant metalwork and nucleated effluent, the process is complex, costly and takes place over many years. Conventional decommissioning methods includes removing fuel from reactor vessels and placing into fuel pools, with other waste such as metalwork being stored underground in concrete blocks.

Nuclear waste from decommissioning is a fundamental issue and ideally should be remedied, current processes are not a long-term sustainable solution, the environmental impact is huge as well as the cost of disposal and storage for the industry. There is a need to enhance current decommissioning methods with the goal of greatly reducing effluent, facilitating the recovery of materials, and creating a circular economy which is key to a sustainable future.

Our Experience With The Nuclear Industry

For 10 years we have been working closely with both Sellafield and NNL in the development of novel electrochemical nuclear decontamination systems, this has culminated in developing two technologies for active deployment on the Sellafield facility.

The scope of our expertise and industry experience has led to us being able to recognise the decommissioning challenges of the nuclear industry. In this partnership we have created a suite of electrochemical decontamination technologies that can be applied to existing downstream nuclear decommissioning processes for use on radioactively contaminated metals and organic matter. The advantage of these technologies is their suitability as a decontamination treatment before disposal or re-use, addressing the current and future issues for nuclear power plants. Our technologies use electricity to replace toxic and costly chemical reagents, they significantly increase the rate of nuclear decontamination whilst significantly reducing the volume of waste effluent generated.

Our Electrochemical Technologies For Nuclear Decommissioning

The decommissioning of a nuclear site involves the decontaminating, dismantling, and demolishing of facilities. We have been developing Electrochemical Nuclear Decontamination technologies named EASD and ELENDES.

In partnership with NNL we have been developing innovative technologies for the Post Operational Clean Out (POCO) phase of a nuclear power plant, the technologies have been demonstrated to significantly reduce radiological hazards and waste.

EASD (Electrolytically Assisted Surface Decontamination)

For the rapid decontamination of the surfaces of stainless-steel vessels and pipes.

A major nuclear decommissioning challenge is the costly decontamination and disposal of large volumes of metal that has become contaminated with radionuclides throughout the lifecycle of a nuclear facility.

Our EASD technology provides a controlled, fast and cost-effective way to dissolve the surface using nitric acid as the media, removing activity from the contaminated metal. The effect that the EASD system exploits is the accelerated electrolytic dissolution of the contaminated metal surface, transferring the radioactive dissolved metal into the nitric acid effluent. This is then processed downstream via conventional methods.

The technology has been developed in both active and in-active trials at NNL (Preston) which demonstrated contaminated items could be treated to free release levels in very short time periods. Future developments are underway for active deployment at Sellafield by 2023.

EASD gives the opportunity to significantly reduce decontamination costs and effluent volume, resulting in free issue decontaminated metal.

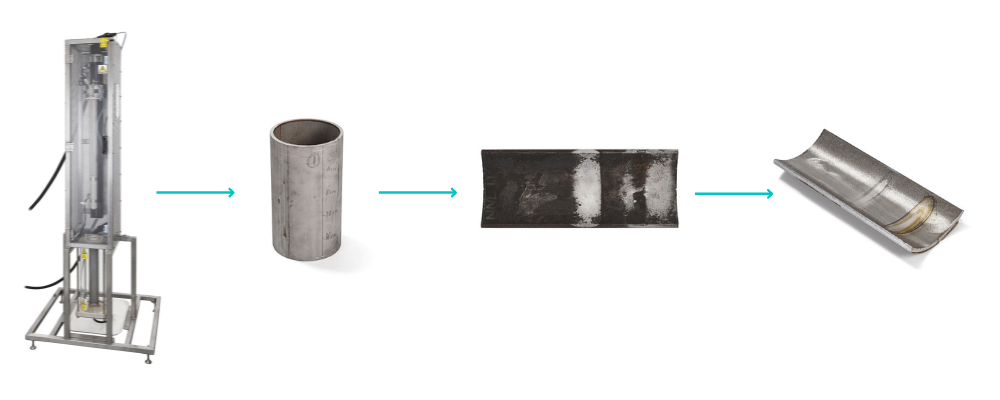

EASD In-Pipe

The application of this technology is for the decontamination of the internal surfaces of steel pipework that have become contaminated with radionuclides. EASD facilitates the removal of a predetermined (typically 10-20 um) surface layer of radioactively contaminated metal within the pipework. This pipework can then either be re-classified or designated as free issue. The system is flexible and able to treat isolated plant areas and has been designed for use on internal pipework and curved surfaces whilst keeping a consistent depth of surface removal. EASD In-pipe removes the surface layer of the contaminated metal, along with the embedded radionuclides, resulting in a treated metal which can be issued as free release, giving significant saving on cost, time and waste effluent.

This technology has been developed through inactive and active trials at NNL Preston between 2019 and 2020, we have further development plans and are working towards active deployment in 2025.

Electrolytically-assisted surface decontamination (IN-PIPE)

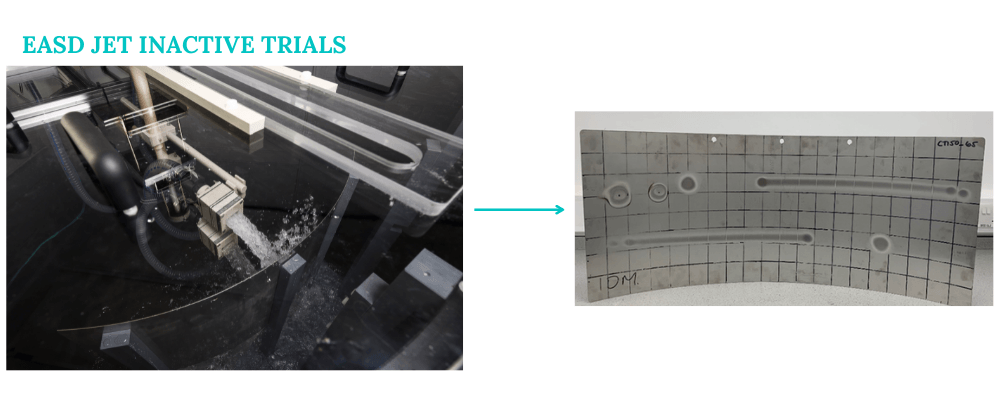

EASD Jet

Our EASD Jet system is intended to treat all metal surfaces, including the internal structural elements of nuclear reactor vessels. It is a highly controllable system, which accelerates the removal of radioactively contaminated surface metalwork, the design of the directional jets gives high throwing power and controlled removal of a layer of stainless steel from the vessel at a defined depth, thus significantly reducing the radiation level of the vessel.

Our EASD Jet system utilises two jet streams of nitric acrid with the current passing through the jets, the metal surface then completes the electrical circuit, and the contaminated metal is then dissolved from the surface. EASD Jet is a non-contact decontamination technique that requires no reagents other than nitric acid acting as the electrolyte, this resulting in straightforward disposal via conventional EARP waste streams.

The technologies effectiveness has been successfully proven during active and inactive trials, at coupon scale and on test pieces representative of the proposed deployment environment, with the active trials also demonstrating free release levels. Our development plans include active deployment on the THORP fuel dissolver vessels at the Sellafield site which is entering a POCO / decontamination phase.

EASD Jet – Case Study:

CHALLENGE: The Sellafield estate has a significant number of contaminated vessels such as oxide fuel dissolvers that provide a challenge for decommissioning. A number of the vessels are either inaccessible to humans or contain nuclear isotopes that have extremely high activity levels.

Decontamination solutions that dissolve high alloy stainless steel grades are difficult to process and waste routing would present a significant challenge both in cost and viability.

SOLUTION: Analysis of the contamination has identified that the diffusion of radionuclides into the surface is limited to the outer layer, typically the top 10-20 um of the substrate. EASD provides a controlled, fast and cost-effective way to dissolve the surface using 4 molar nitric acid as the media. The stainless steel is inert to the acid except in the areas where the patented EASD waveform is applied.

STATUS: EASD Jet has been selected as the only technology currently under assessment that is suitable for in-situ demonstration. The engineering study has been completed and full-scale demonstration of the deployment arm and control system is in progress.

NEXT STEPS: Once deployed and proven in the first application at Sellafield the EASD Jet has been selected as a prime process for the decontamination of high activity volume treatment.

Electrolytically-assisted surface decontamination

ELENDES (Electrochemical Nuclear Decontamination

For the removal of contaminated organic matter from aqueous effluent prior to downstream processing.

The ELENDES technology is the electrochemical oxidation of insoluble organic waste material found at nuclear sites. The process removes the organic matter containing radioactive content from waste material and concentrates it into an acidic effluent, this is then suitable for conventional downstream processing. Organic radioactive waste can occur in solid and liquid form, originating from such items as protective gloves and clothing, laboratory equipment, lubricants, oil waste, paints and solvents. The electrochemical process employed allows multiple batches of material to be treated, the retained activity accumulates in a concentrated acidic liquid effluent and at a predetermined point is removed for conventional downstream treatment.

ELENDES is an innovative electrochemical nuclear decontamination technology that safely removes contaminated organic matter at the end of life. Simply put, the ELENDES process enables destruction of contaminated organic matter, converting the material from something hazardous and expensive to dispose of into a form that can be treated via traditional methods.

The ELENDES process uses electrochemically generated silver (II) to oxidise organic waste streams, which is generated from silver in a nitic acid solution. The silver nitrate is oxidised to the silver (II) state and is then mixed with the organic waste stream, the waste stream is then oxidised to CO2 and any radioactive species remains in the liquor. The silver (II) is then recovered (down to parts per billion levels) from the concentrated effluent prior to downstream processing by means of a separate extraction process.

The success of our active trials gave an increased understanding of the capabilities and advantages electrochemical technologies can bring to the nuclear industry. The trials were demonstrated with a range of difficult organic waste streams representative of that seen on plant.

Both EASD and ELENDES are effective solutions that facilitate safer and quicker decontamination methods within the nuclear environment. Targeting waste volumes is a goal for reducing decommissioning costs, our technologies address industry needs by reducing the long-term costs of nuclear waste disposal and minimising the environmental footprint of nuclear decommissioning activities by means of final waste volumes.

Discuss This Technology Further

OR Speak to us on: +44 (0)151 347 2900 / By email: info@ctechinnovation.com